-

Packaging for ice cream wins international acclaim

Norwegian ice cream producer Diplom-Is wins the international award for best packaging solution, which is produced by Berry Superfos.

-

Berry Superfos website is moving to a new home soon!

Berry Superfos website will be relocating to our parent company’s website, Berry Global, at berryglobal.com later this year.

-

New pudding pot extends shelf life and saves on plastic

Valio is launching a new pot for its protein puddings. It combines cardboard and plastic with a unique coating to ensure a 120-day shelf life.

-

New versatile tray range

Berry Superfos introduces the ½ Gastro tray range, offering exceptional versatility in depth, volume, and colour, catering to diverse needs across the food industry.

-

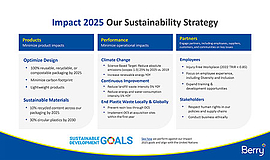

Berry Superfos advances circular economy goals with new initiatives

Aiming for 100% reusable, recyclable, or compostable packaging by 2025, Berry Superfos is set to remove metal handles and the colour carbon black in 2024.

-

Renowned brewery chooses the reusable SuperCup

The French brewery Brasserie Licorne, known for its unicorn-themed branding, has opted for the SuperCup for serving its quality beers, ciders and energy drinks.

-

Beissier switches to 30% recycled plastic

French plaster producer Beissier has transitioned one of its product lines to SuperLift® containers made with 30% recycled plastic and featuring the RecyClass label.

-

Berry Superfos launches Reusable Tableware Range for the food service industry

Read about our new revolutionary range of reusable bowls and lids, redefining the way restaurant food is served, enjoyed and packaged.

-

Re-designed cups for dairy producer TINE win their second award

The recyclable sleeve on Berry Superfos cups for TINE, a Norwegian dairy leader, won the 2023 AWA International Award.

-

Berry Superfos wins two more prestigious awards for recycling project

The closed-loop system project by Berry Superfos, aimed at recycling paint containers, has now been honoured with five distinct awards for its innovative circular solution.

-

Berry Superfos leads the way in food safety

Via BRC certification and other measures, we remain committed to maintain high standards of hygiene and quality for food packaging

-

A perfect cup for confectionery and fun

Originally designed for beverages, the reusable SuperCup has just made its debut in the confectionery market.

-

The reusable SuperCup is attending the Rugby World Cup

InfinyCup has partnered with Berry Superfos to equip two major stadiums with the reusable SuperCup for beer and soft drinks during the 10th Rugby World Cup held in France.

-

Elevate your brand with the new reusable Berry Cup Range for hot and cold drinks

Now you can switch from single-use to reusable cups for your brand with the new stylish and functional Berry Cup Range.

-

Bring your next packaging project to life, enhance your creativity and drive packaging innovation with the Berry Superfos 3D Design Studio

Register now to save time and unleash your creativity.

-

Freezer-safe packaging for fruit juice concentrates

Gat Foods, supplier for the global beverage industry, has chosen Berry Superfos as packaging partner for its fruit juice concentrates to ensure freezer safety.

-

We are extremely satisfied with the quality and design of the UniPak container

Bajro Ćatić, CEO of Ćatić Company which recently switched to UniPak for its popular Waltz cream rolls.

-

We decided to stay with the SuperLift® container but change its composition to include recycled content

CEO Alexander Axelsson, Everbrand, about the switch to PCR-content containers for IS-FRITT de-icing products.

-

We want all our packaging to be made of renewable or recycled material by 2025. Our new pot for three of our products is an important step towards this goal.

Bjørn Malm, head of sustainability at dairy company TINE

-

Heinz and Tesco launch pioneering recycling project

Berry Global is part of a first of its kind pilot project launched by Heinz and Tesco to recycle more soft plastics in the United Kingdom.

-

Qbo coffee switches to coffee capsules made from renewable materials

German coffee producer Tchibo chose Berry Superfos to produce coffee capsules made from renewable materials for their Qbo brand.

-

Non-carbon is the new black

Ice cream producer Diplom-Is makes recycling possible by opting for a new non-carbon black colour for its containers.

-

Our customers will benefit from faster testing of raw materials for food product packaging

The new Berry Superfos testing laboratory has obtained accreditation in the field of chemical testing and sampling of plastic products.

-

19% weight reduction for yoghurt and desserts packaging

For sustainability reasons, dairy producer Milchwerke Schwaben joined forces with Berry Superfos to reduce the weight of their 1 kg packaging.

-

Iconic pot for Allioli garlic mayonnaise now includes 25% recycled polypropylene

Food producer Choví launches more sustainable packaging developed in partnership with Berry Superfos

-

The wet wipes container is outstanding: airtight, durable and reusable

Hitam in France is impressed with the design expertise of Berry Superfos.

-

Sign up for our newsletter

Contact us here:

Grand opening celebration at RPC Superfos Balkan

This spring RPC Superfos Balkan celebrated a milestone inaugurating its fully high-tech facility in Gračanica, Bosnia & Herzegovina. Despite past challenges, RPC Superfos Balkan may today proudly look back on an exciting journey which began in December 2013 when the company, then known as Helioplast, became part of the RPC Group.

Double-digit growth rate

At the time, RPC Group rightly saw great potential for Helioplast in the RPC Superfos Division, making it possible to offer a larger selection of high quality rigid plastic packaging solutions for customers in the wider Balkan region.

A EUR 3.3 million investment in the premises has now turned RPC Superfos Balkan into a modern production facility equipped with the very latest technology and IT control systems. The number of tons produced have increased by more than 75 per cent; from 2,600 in 2013 to 4,500 in 2016 and a growth of about 15 per cent is expected for 2017/18. Over the past few years, the company has experienced a double-digit growth rate and turnover in 2016 was nearly doubled compared to 2013.

René Valentin, CEO of RPC Superfos, is more than content with the progress from 2013 to 2017:

“We congratulate management and staff at RPC Superfos Balkan with the grand opening and wish them all the best for a continued successful development and prosperous business.”

Overcoming difficulties along the way

However, the exciting journey to today’s success story has not been without its challenges for RPC Superfos Balkan. The post-war conditions have been far from easy, with the added problem that extreme rain in 2014 has twice caused flooding of the newly-completed production facility. As a precaution, the floor height of the 3,000 m2 production area has recently been significantly raised. This preventive measure was completed in only seven months’ time.

Positive outlook for business

Regional Director, Jean Scandella, RPC Superfos French /South East, is pleased with the positive outlook for our business:

“Through the upgraded facilities and thanks to our dedicated staff at RPC Superfos Balkan, we are now in a strong position to meet the increased demand for plastic packaging in the greater Balkan region. We have achieved a great deal in short time and there is potential for more to come. Certainly, we are delighted with the spillover effect our success has on jobs and economic growth for the local community.”

The essential points

In December 2013, the RPC Group acquired the small family company Helioplast. Since July 2014, the company has been trading as RPC Superfos Balkan within RPC Superfos Region French/South East. Under the wings of RPC Superfos, the company has developed in leaps and bounds and is, today, acknowledged as a large and successful company with significant international business. Boasting 12,000 square meters and 30 injection machines, the modern facility is in an excellent position to pursue further growth.

On the grand opening celebration in May 2017, local business people, employees, customers, politicians as well as representatives of the Royal British Embassy were among the guests of the event hosted by René Valentin CEO of RPC Superfos, Jean Scandella, Regional Director Region French/South East, RPC Superfos and Suad Helić, Key Account Manager, former owner and Managing Director, RPC Superfos Balkan.

Want to know more?

- Zbigniew Hryniewicz

- Sales Director

- Berry Superfos

- Phone: +48 54 4291000

Want to know more?

- Birthe Bebe Nielsen

- Product, Marketing &

- Communications Director

- Berry Superfos

- Phone: +45 5911 1110

Hi, I’m CombiPac.

I combine plastic with cardboard. I’m grease resistant and I can shape up: Cup or a tray, I’m the one that you want. Get to know me better...

Would you like to be contacted?

- Berry Superfos

- Head Office

- Spotorno Allé 8

- DK-2630 Taastrup

- Denmark

- General Inquiries

- E-mail: Superfos@berryglobal.com

- Phone: +45 5911 1110

- Fax: +45 5911 1180

- Sales Inquiries

- E-mail: SuperfosSales@berryglobal.com

- Phone: +45 5911 1110

- Fax: +45 5911 1180