-

Packaging for ice cream wins international acclaim

Norwegian ice cream producer Diplom-Is wins the international award for best packaging solution, which is produced by Berry Superfos.

-

Berry Superfos website is moving to a new home soon!

Berry Superfos website will be relocating to our parent company’s website, Berry Global, at berryglobal.com later this year.

-

New pudding pot extends shelf life and saves on plastic

Valio is launching a new pot for its protein puddings. It combines cardboard and plastic with a unique coating to ensure a 120-day shelf life.

-

New versatile tray range

Berry Superfos introduces the ½ Gastro tray range, offering exceptional versatility in depth, volume, and colour, catering to diverse needs across the food industry.

-

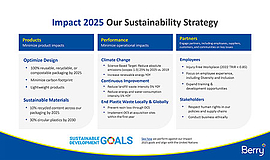

Berry Superfos advances circular economy goals with new initiatives

Aiming for 100% reusable, recyclable, or compostable packaging by 2025, Berry Superfos is set to remove metal handles and the colour carbon black in 2024.

-

Renowned brewery chooses the reusable SuperCup

The French brewery Brasserie Licorne, known for its unicorn-themed branding, has opted for the SuperCup for serving its quality beers, ciders and energy drinks.

-

Beissier switches to 30% recycled plastic

French plaster producer Beissier has transitioned one of its product lines to SuperLift® containers made with 30% recycled plastic and featuring the RecyClass label.

-

Berry Superfos launches Reusable Tableware Range for the food service industry

Read about our new revolutionary range of reusable bowls and lids, redefining the way restaurant food is served, enjoyed and packaged.

-

Re-designed cups for dairy producer TINE win their second award

The recyclable sleeve on Berry Superfos cups for TINE, a Norwegian dairy leader, won the 2023 AWA International Award.

-

Berry Superfos wins two more prestigious awards for recycling project

The closed-loop system project by Berry Superfos, aimed at recycling paint containers, has now been honoured with five distinct awards for its innovative circular solution.

-

Berry Superfos leads the way in food safety

Via BRC certification and other measures, we remain committed to maintain high standards of hygiene and quality for food packaging

-

A perfect cup for confectionery and fun

Originally designed for beverages, the reusable SuperCup has just made its debut in the confectionery market.

-

The reusable SuperCup is attending the Rugby World Cup

InfinyCup has partnered with Berry Superfos to equip two major stadiums with the reusable SuperCup for beer and soft drinks during the 10th Rugby World Cup held in France.

-

Elevate your brand with the new reusable Berry Cup Range for hot and cold drinks

Now you can switch from single-use to reusable cups for your brand with the new stylish and functional Berry Cup Range.

-

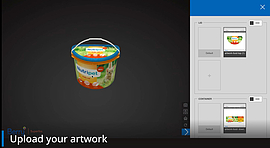

Bring your next packaging project to life, enhance your creativity and drive packaging innovation with the Berry Superfos 3D Design Studio

Register now to save time and unleash your creativity.

-

Freezer-safe packaging for fruit juice concentrates

Gat Foods, supplier for the global beverage industry, has chosen Berry Superfos as packaging partner for its fruit juice concentrates to ensure freezer safety.

-

We are extremely satisfied with the quality and design of the UniPak container

Bajro Ćatić, CEO of Ćatić Company which recently switched to UniPak for its popular Waltz cream rolls.

-

We decided to stay with the SuperLift® container but change its composition to include recycled content

CEO Alexander Axelsson, Everbrand, about the switch to PCR-content containers for IS-FRITT de-icing products.

-

We want all our packaging to be made of renewable or recycled material by 2025. Our new pot for three of our products is an important step towards this goal.

Bjørn Malm, head of sustainability at dairy company TINE

-

Heinz and Tesco launch pioneering recycling project

Berry Global is part of a first of its kind pilot project launched by Heinz and Tesco to recycle more soft plastics in the United Kingdom.

-

Qbo coffee switches to coffee capsules made from renewable materials

German coffee producer Tchibo chose Berry Superfos to produce coffee capsules made from renewable materials for their Qbo brand.

-

Non-carbon is the new black

Ice cream producer Diplom-Is makes recycling possible by opting for a new non-carbon black colour for its containers.

-

Our customers will benefit from faster testing of raw materials for food product packaging

The new Berry Superfos testing laboratory has obtained accreditation in the field of chemical testing and sampling of plastic products.

-

19% weight reduction for yoghurt and desserts packaging

For sustainability reasons, dairy producer Milchwerke Schwaben joined forces with Berry Superfos to reduce the weight of their 1 kg packaging.

-

Iconic pot for Allioli garlic mayonnaise now includes 25% recycled polypropylene

Food producer Choví launches more sustainable packaging developed in partnership with Berry Superfos

-

The wet wipes container is outstanding: airtight, durable and reusable

Hitam in France is impressed with the design expertise of Berry Superfos.

-

Sign up for our newsletter

Contact us here:

3D software key to successful design

Creative processes involve many steps and typically, one idea leads to the next. Consequently, it is a great help if you can test how colour, text font and graphic elements actually work on your pack - in the virtual world and in 3D.

The TurnAvisual 3D software makes it possible. Recently, the popcorn producer Food Products International S.r.l. has used it to create artwork design for popcorn tubs. The process has been smooth and easy, and the eye-catching result is closely linked to the online tool. Marketing Manager Valentina Vezzoli from Food Products International says:

“The 3D software tool has been the key to our successful artwork design projects. I warmly recommend it to anyone working with the graphic part of packaging.”

See all changes step by step

Food Products International has made use of TurnAvisual for two artwork design projects: One was about a design from scratch for a new range, Popz Gran Gourmet; the other an enhancement of an existing artwork. In both cases, the packaging solution is the versatile UniPak.

“From the render in 3D, we could see exactly how a suggested idea would turn out on the popcorn tub. What you initially think will look good, does not necessarily have the desired effect when you view the tub from all perspectives. Each phase entailed some changes until we reached the final result,” Valentina Vezzoli explains.

Time saving teamwork

A whole group of decisions makers from sales, marketing, operations and production have shared ideas and commented on each artwork suggestions online. Everyone found it quick, cost efficient and easy to work with TurnAvisual. The tool makes it possible to send conceptual feedback and to select the best suggestion.

“Eight decision makers from our various departments have been involved in the artwork design processes and it took only three weeks to go from start to finish for the re-design and less than six weeks for the new project. Working with TurnAvisual saves a lot of time and speeds up our time-to-market,” Valentina Vezzoli explains.

Food Products International is the Italian branch of the American company Popz which is controlled by Jim Watkins – the man who in the late seventies invented microwave popcorn.

Associated files

Want to know more?

- Phone:

Hi I’m Thor,

I’m round and as strong as my name indicates. Use me for a variety of food, soups included – I’m handy and liquid tight. Get to know me better...

Would you like to be contacted?

- Berry Superfos

- Head Office

- Spotorno Allé 8

- DK-2630 Taastrup

- Denmark

- General Inquiries

- E-mail: Superfos@berryglobal.com

- Phone: +45 5911 1110

- Fax: +45 5911 1180

- Sales Inquiries

- E-mail: SuperfosSales@berryglobal.com

- Phone: +45 5911 1110

- Fax: +45 5911 1180