-

Packaging for ice cream wins international acclaim

Norwegian ice cream producer Diplom-Is wins the international award for best packaging solution, which is produced by Berry Superfos.

-

Berry Superfos website is moving to a new home soon!

Berry Superfos website will be relocating to our parent company’s website, Berry Global, at berryglobal.com later this year.

-

New pudding pot extends shelf life and saves on plastic

Valio is launching a new pot for its protein puddings. It combines cardboard and plastic with a unique coating to ensure a 120-day shelf life.

-

New versatile tray range

Berry Superfos introduces the ½ Gastro tray range, offering exceptional versatility in depth, volume, and colour, catering to diverse needs across the food industry.

-

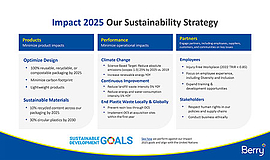

Berry Superfos advances circular economy goals with new initiatives

Aiming for 100% reusable, recyclable, or compostable packaging by 2025, Berry Superfos is set to remove metal handles and the colour carbon black in 2024.

-

Renowned brewery chooses the reusable SuperCup

The French brewery Brasserie Licorne, known for its unicorn-themed branding, has opted for the SuperCup for serving its quality beers, ciders and energy drinks.

-

Beissier switches to 30% recycled plastic

French plaster producer Beissier has transitioned one of its product lines to SuperLift® containers made with 30% recycled plastic and featuring the RecyClass label.

-

Berry Superfos launches Reusable Tableware Range for the food service industry

Read about our new revolutionary range of reusable bowls and lids, redefining the way restaurant food is served, enjoyed and packaged.

-

Re-designed cups for dairy producer TINE win their second award

The recyclable sleeve on Berry Superfos cups for TINE, a Norwegian dairy leader, won the 2023 AWA International Award.

-

Berry Superfos wins two more prestigious awards for recycling project

The closed-loop system project by Berry Superfos, aimed at recycling paint containers, has now been honoured with five distinct awards for its innovative circular solution.

-

Berry Superfos leads the way in food safety

Via BRC certification and other measures, we remain committed to maintain high standards of hygiene and quality for food packaging

-

A perfect cup for confectionery and fun

Originally designed for beverages, the reusable SuperCup has just made its debut in the confectionery market.

-

The reusable SuperCup is attending the Rugby World Cup

InfinyCup has partnered with Berry Superfos to equip two major stadiums with the reusable SuperCup for beer and soft drinks during the 10th Rugby World Cup held in France.

-

Elevate your brand with the new reusable Berry Cup Range for hot and cold drinks

Now you can switch from single-use to reusable cups for your brand with the new stylish and functional Berry Cup Range.

-

Bring your next packaging project to life, enhance your creativity and drive packaging innovation with the Berry Superfos 3D Design Studio

Register now to save time and unleash your creativity.

-

Freezer-safe packaging for fruit juice concentrates

Gat Foods, supplier for the global beverage industry, has chosen Berry Superfos as packaging partner for its fruit juice concentrates to ensure freezer safety.

-

We are extremely satisfied with the quality and design of the UniPak container

Bajro Ćatić, CEO of Ćatić Company which recently switched to UniPak for its popular Waltz cream rolls.

-

We decided to stay with the SuperLift® container but change its composition to include recycled content

CEO Alexander Axelsson, Everbrand, about the switch to PCR-content containers for IS-FRITT de-icing products.

-

We want all our packaging to be made of renewable or recycled material by 2025. Our new pot for three of our products is an important step towards this goal.

Bjørn Malm, head of sustainability at dairy company TINE

-

Heinz and Tesco launch pioneering recycling project

Berry Global is part of a first of its kind pilot project launched by Heinz and Tesco to recycle more soft plastics in the United Kingdom.

-

Qbo coffee switches to coffee capsules made from renewable materials

German coffee producer Tchibo chose Berry Superfos to produce coffee capsules made from renewable materials for their Qbo brand.

-

Non-carbon is the new black

Ice cream producer Diplom-Is makes recycling possible by opting for a new non-carbon black colour for its containers.

-

Our customers will benefit from faster testing of raw materials for food product packaging

The new Berry Superfos testing laboratory has obtained accreditation in the field of chemical testing and sampling of plastic products.

-

19% weight reduction for yoghurt and desserts packaging

For sustainability reasons, dairy producer Milchwerke Schwaben joined forces with Berry Superfos to reduce the weight of their 1 kg packaging.

-

Iconic pot for Allioli garlic mayonnaise now includes 25% recycled polypropylene

Food producer Choví launches more sustainable packaging developed in partnership with Berry Superfos

-

The wet wipes container is outstanding: airtight, durable and reusable

Hitam in France is impressed with the design expertise of Berry Superfos.

-

Sign up for our newsletter

Contact us here:

Yet another Berry Superfos facility certifies mass balance approach

More used materials, including plastic, need to be recycled to ensure society’s all-important transformation from a throwaway economy into a circular one. To gear up for this transformation, Berry Superfos is using the mass balance approach to integrate circular polymers and is certifying its facilities according to ISCC PLUS (International Sustainability & Carbon Certification), a third-party standard well-recognised by all stakeholders for recycled and bio-based materials.

The most recent addition to the list of ISCC PLUS certified Berry Superfos facilities is located in Bouxwiller in eastern France. Here we manufacture thermoformed coffee capsules and packaging solutions for food products. Nicolas Dal Degan, Regional Director of Berry Superfos Beverage Systems, says:

“We are very pleased that our Bouxwiller facility now holds an ISCC PLUS certification. This enables us to offer customers in the food and beverage industry solutions made with advanced recycled materials based on the mass balance approach in a transparent way. Third-party certifications like ISCC PLUS build trust, which is crucial, particularly for new methods such as the use of circular polymer for food packaging,”

Ensures traceability along the supply chain

The ISCC PLUS certification ensures credible claims for circular materials by providing traceability along the supply chain and verifying compliance with environmental and social standards. For companies like Berry Superfos which use the mass balance approach, ISCC PLUS certification verifies that the mass balance accounting follows predefined and transparent rules.

You will save virgin materials and reduce landfill waste

Currently, the most common form of advanced recycling requiring an ISCC PLUS certification is pyrolysis which breaks down used plastic into chemical feedstocks of virgin-quality, recycled polypropylene and polyethylene. These are then included in the production of new plastic packaging solutions. Already, Berry Superfos is working with several customers on pioneering projects to reap the benefits of this new technology.

When food and beverage producers opt for a packaging solution with recycled content, they help to reduce the amount of plastic ending up in landfill and also save virgin materials.

If you want to use advanced recycled material in your food and beverage packaging and make claims about its benefits, you are also required to have an ISCC PLUS certification of your own covering your food production facility.

Certificates available here

In case you need the actual ISCC PLUS certificates from Berry Superfos, you can find them here.

Want to know more?

- Nicolas Dal Degan

- Operations Director

- Food Service

- Phone: +33 3 8871 7800

Hi, I’m SuperFlex.

I’m an industrial classic; as versatile as it gets and extremely easy to open and close. Get to know me better...

Would you like to be contacted?

- Berry Superfos

- Head Office

- Spotorno Allé 8

- DK-2630 Taastrup

- Denmark

- General Inquiries

- E-mail: Superfos@berryglobal.com

- Phone: +45 5911 1110

- Fax: +45 5911 1180

- Sales Inquiries

- E-mail: SuperfosSales@berryglobal.com

- Phone: +45 5911 1110

- Fax: +45 5911 1180