-

Packaging for ice cream wins international acclaim

Norwegian ice cream producer Diplom-Is wins the international award for best packaging solution, which is produced by Berry Superfos.

-

Berry Superfos website is moving to a new home soon!

Berry Superfos website will be relocating to our parent company’s website, Berry Global, at berryglobal.com later this year.

-

New pudding pot extends shelf life and saves on plastic

Valio is launching a new pot for its protein puddings. It combines cardboard and plastic with a unique coating to ensure a 120-day shelf life.

-

New versatile tray range

Berry Superfos introduces the ½ Gastro tray range, offering exceptional versatility in depth, volume, and colour, catering to diverse needs across the food industry.

-

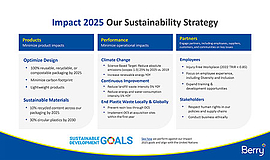

Berry Superfos advances circular economy goals with new initiatives

Aiming for 100% reusable, recyclable, or compostable packaging by 2025, Berry Superfos is set to remove metal handles and the colour carbon black in 2024.

-

Renowned brewery chooses the reusable SuperCup

The French brewery Brasserie Licorne, known for its unicorn-themed branding, has opted for the SuperCup for serving its quality beers, ciders and energy drinks.

-

Beissier switches to 30% recycled plastic

French plaster producer Beissier has transitioned one of its product lines to SuperLift® containers made with 30% recycled plastic and featuring the RecyClass label.

-

Berry Superfos launches Reusable Tableware Range for the food service industry

Read about our new revolutionary range of reusable bowls and lids, redefining the way restaurant food is served, enjoyed and packaged.

-

Re-designed cups for dairy producer TINE win their second award

The recyclable sleeve on Berry Superfos cups for TINE, a Norwegian dairy leader, won the 2023 AWA International Award.

-

Berry Superfos wins two more prestigious awards for recycling project

The closed-loop system project by Berry Superfos, aimed at recycling paint containers, has now been honoured with five distinct awards for its innovative circular solution.

-

Berry Superfos leads the way in food safety

Via BRC certification and other measures, we remain committed to maintain high standards of hygiene and quality for food packaging

-

A perfect cup for confectionery and fun

Originally designed for beverages, the reusable SuperCup has just made its debut in the confectionery market.

-

The reusable SuperCup is attending the Rugby World Cup

InfinyCup has partnered with Berry Superfos to equip two major stadiums with the reusable SuperCup for beer and soft drinks during the 10th Rugby World Cup held in France.

-

Elevate your brand with the new reusable Berry Cup Range for hot and cold drinks

Now you can switch from single-use to reusable cups for your brand with the new stylish and functional Berry Cup Range.

-

Bring your next packaging project to life, enhance your creativity and drive packaging innovation with the Berry Superfos 3D Design Studio

Register now to save time and unleash your creativity.

-

Freezer-safe packaging for fruit juice concentrates

Gat Foods, supplier for the global beverage industry, has chosen Berry Superfos as packaging partner for its fruit juice concentrates to ensure freezer safety.

-

We are extremely satisfied with the quality and design of the UniPak container

Bajro Ćatić, CEO of Ćatić Company which recently switched to UniPak for its popular Waltz cream rolls.

-

We decided to stay with the SuperLift® container but change its composition to include recycled content

CEO Alexander Axelsson, Everbrand, about the switch to PCR-content containers for IS-FRITT de-icing products.

-

We want all our packaging to be made of renewable or recycled material by 2025. Our new pot for three of our products is an important step towards this goal.

Bjørn Malm, head of sustainability at dairy company TINE

-

Heinz and Tesco launch pioneering recycling project

Berry Global is part of a first of its kind pilot project launched by Heinz and Tesco to recycle more soft plastics in the United Kingdom.

-

Qbo coffee switches to coffee capsules made from renewable materials

German coffee producer Tchibo chose Berry Superfos to produce coffee capsules made from renewable materials for their Qbo brand.

-

Non-carbon is the new black

Ice cream producer Diplom-Is makes recycling possible by opting for a new non-carbon black colour for its containers.

-

Our customers will benefit from faster testing of raw materials for food product packaging

The new Berry Superfos testing laboratory has obtained accreditation in the field of chemical testing and sampling of plastic products.

-

19% weight reduction for yoghurt and desserts packaging

For sustainability reasons, dairy producer Milchwerke Schwaben joined forces with Berry Superfos to reduce the weight of their 1 kg packaging.

-

Iconic pot for Allioli garlic mayonnaise now includes 25% recycled polypropylene

Food producer Choví launches more sustainable packaging developed in partnership with Berry Superfos

-

The wet wipes container is outstanding: airtight, durable and reusable

Hitam in France is impressed with the design expertise of Berry Superfos.

-

Sign up for our newsletter

Contact us here:

Bottles & paint cans: Easy purchasing within RPC

RPC Superfos is supplying 1 and 2.5 litre Paintainers; RPC Promens Industrial Rushden is producing a 1 litre bottle; and RPC PET Power has been able to meet the need for a 1 litre PET bottle as well. All these packs go to Roar Advance Finishing, a newly-established car care and finishing specialist in the UK. The company sources the majority of its packaging solutions from one supplier, the RPC Group, and enjoys the versatility of the offerings.

All packs reflect the quality image of the company

The variety of car care and finishing products calls for a number of different packaging formats but essential requirements for all packs are that they are practical, functional and reflect the quality image of the company, as director Rob Wilkinson, Roar Advance Finishing, explains:

“For these types of specialist products it is particularly important that the packaging is robust and provides effective protection. At the same time, the packs need to look good and be easy to use. Having worked with RPC before, I knew we could rely on the company to meet these requirements reliably and consistently.”

The packs are being used for products such as Extreme Wax (the PET bottle), Extreme Fine Grade for removal of swirl marks (the High Density Polyethylene bottle, HDPE) and Speed Cut Compound for removal of sanding marks (the Paintainer paint can from RPC Superfos). All feature Roar’s distinctive orange and black colours to create high impact branding and effective on-shelf presence.

Different packs from virtually one supplier

The HDPE and PET bottles are produced in orange and black respectively and both incorporate a large decoration area for glossy wraparound labels. For the paint cans, the use of in-mould labelling provides all over coverage for a high quality decorative effect combined with room for detailed instructions on usage of the product.

“Plastic has proved to be a highly versatile material in meeting the needs of many of our products. RPC is equally versatile in enabling us to source so many different pack types from one supplier and the pedigree of the company’s technical abilities is evident in all these containers,” concludes Rob Wilkinson.

Established by a group of professionals with over 30 years’ experience within the car refinish, automotive and composite finishing industries, Roar has developed a wide range of both professional and consumer products for the global market.

Associated files

Want to know more?

Want to know more?

Want to know more?

Want to know more?

Want to know more?

- Anne-Marie Rooney

- Commercial Support Manager

- UK

- Phone: +44 7971 117701

Want to know more?

Want to know more?

- Jenna Callaghan

- Sales Development Executive

- UK

- Phone: +44 797 111 7718

Hi, I’m SuperLight.

It’s not just something they say – I really am ultra light. I’m a thin wall packaging and leave a smaller carbon footprint behind. Get to know me better...

Would you like to be contacted?

- Berry Superfos

- Head Office

- Spotorno Allé 8

- DK-2630 Taastrup

- Denmark

- General Inquiries

- E-mail: Superfos@berryglobal.com

- Phone: +45 5911 1110

- Fax: +45 5911 1180

- Sales Inquiries

- E-mail: SuperfosSales@berryglobal.com

- Phone: +45 5911 1110

- Fax: +45 5911 1180